Design Futures

Establish a visual project plan. Run the project from conceptualisation to delivery. This must include 3 rounds of prototyping, testing and iteration.

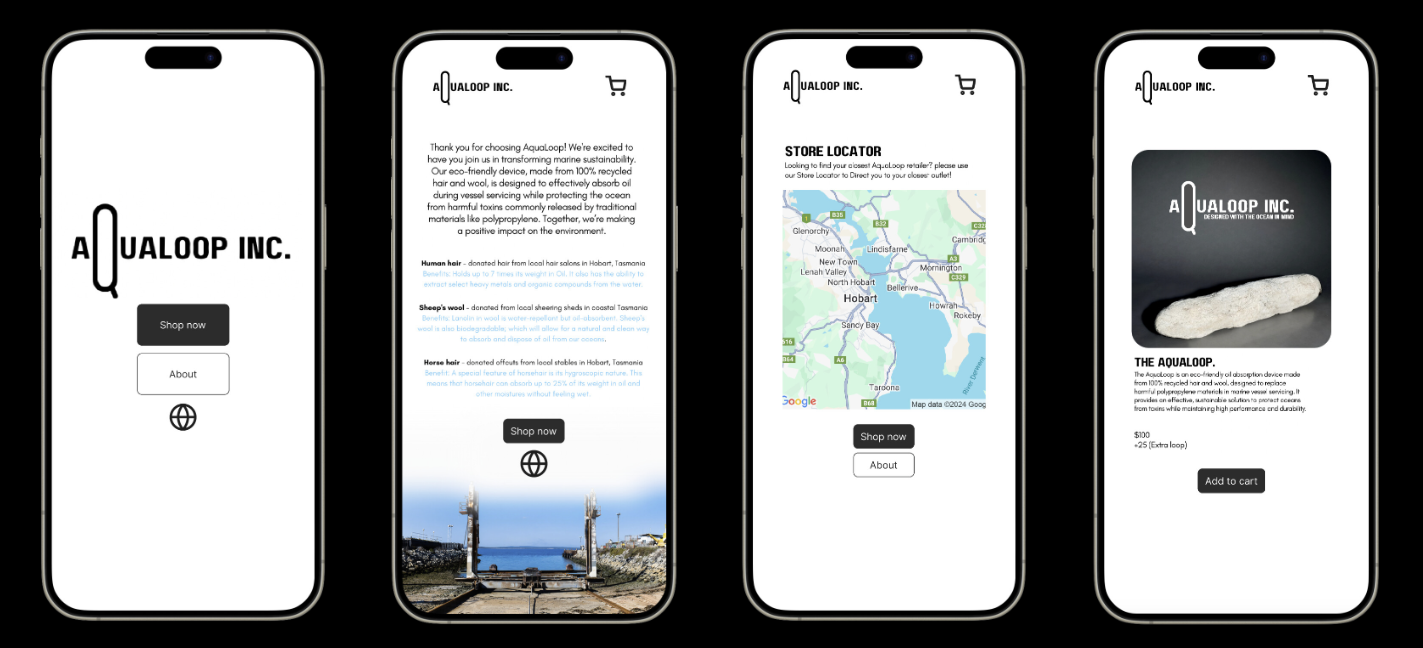

With locally recoursed waste materials I look to reshape a current practice within marine industries. To service a vessel in the ocean currently, there is a device containing toxic materials like Polypropylene to absorb oil that is deployed into the ocean surrounding the boat in aid of collecting the unused oil.

Polypropylene slowly releases these toxins into the ocean.

With my device, I will be able to mimic the same process with a device made out of 100% recycled hair and wool to stop the need for these pellets.

Exploring the use of waste fibres such as hair and wool to reduce pollution for local application.

After my device has served its purpose of collecting oil. The operators will dispose of the contents into a collection drum that allows the hair and wool to decompose into the oil. From here the oil is transferred to the South Australian OIl Recycling Centre where the donations are repurposed into mechanical lubrication oils, biofuels, machinery fuel ect.

Lanolin in wool is water-repellant but oil-absorbent. Sheep's wool is also biodegradable.

Hair holds up to 7 times its weight in Oil. It also has the ability to extract select heavy metals and organic compounds from the water.

Insight into processing

-

First, we collect all of our donations from across multiple participating salons alongside sheering sheds from across Tasmania.

-

From here, we go through and wash all materials with water to filter out any non-hair materials.

-

Then, we needle fleece the materials together into their form and finish the construction of the product ready for distribution.

-

Finally, once the product has arrived to its destination the product is ready for use.

-

Once the product has fulfilled its purpose dispose of the product into the decomposition bin where it sits for a specific duration of time before being transported to a filtration centre to be repurposed.

Prototyping

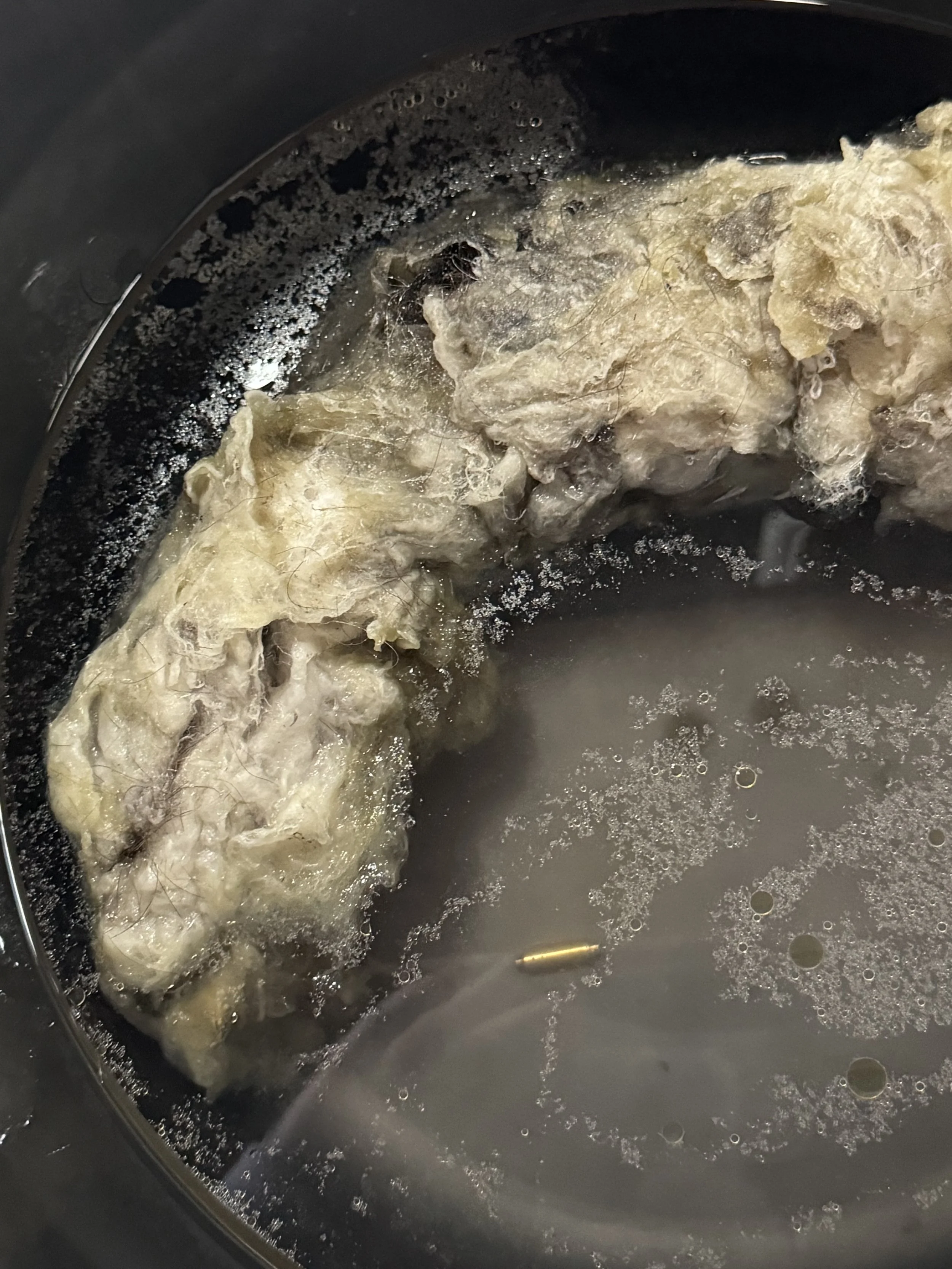

To conduct the testing phase I acquired some old used mechanical oil and began to filter through the AquaLoop. Immediately I noticed the materials absorbed the oil on its first swipe through.

During this test, I witnessed the water filtering through leaving the oil within the filter. And I also noticed the oil made the device's construction more durable, it held its structure easier once it was saturated in oil.